In high-reliability industries, procuring and preparing electronic components for use in end products demands a rigorous approach to ensure reliability and performance.

Traditional supply chains often involve multiple vendors for sourcing and BGA reballing, leading to increased lead times, higher risks, and inconsistencies in quality.

A more efficient solution is partnering with a global, single-source provider that integrates these services under one roof. This streamlined approach ensures faster turnaround times, standardized reballing processes, and reduced supply chain complexity—all of which are essential in industries where performance and reliability are non-negotiable.

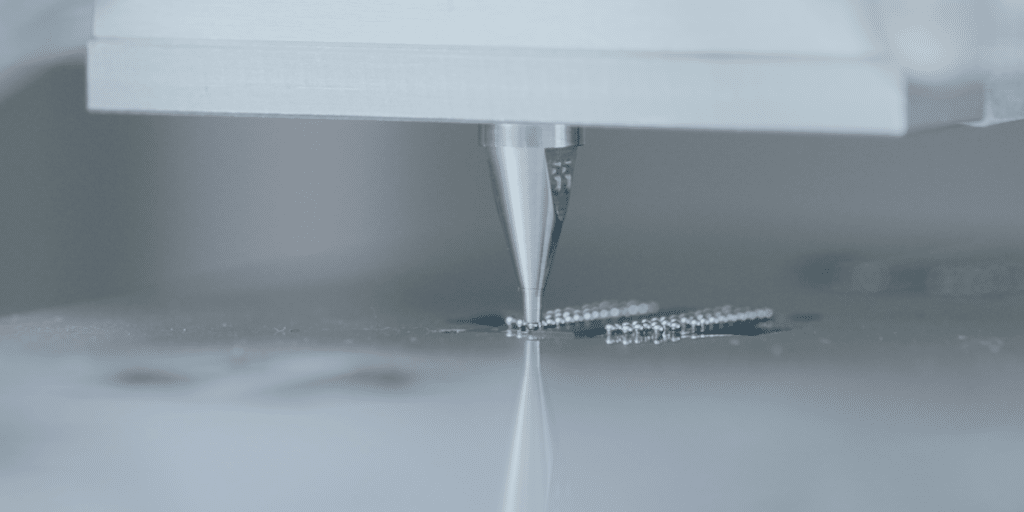

The Lead Time Challenge in BGA Reballing

In conventional BGA reballing workflows, components are sent to multiple vendors, each handling a different stage of the process. This fragmented approach introduces unnecessary delays and risks, including:

- Extended shipping times: Transferring components between facilities adds logistical delays.

- Inconsistent reballing standards: Variability in techniques across providers can lead to quality issues.

- Regulatory challenges: Cross-border shipments may face compliance hurdles, slowing critical projects.

For industries such as aerospace, defense, and medical technology, where component reliability is mission-critical, these inefficiencies can lead to costly delays and increased risk.

How a One-Stop Shop for sourcing and BGA Reballing Solves These Issues

Partnering with a one-stop shop for BGA sourcing and reballing eliminates these challenges and provides key advantages:

- Faster Lead Times: Consolidating BGA sourcing and reballing with one partner eliminates shipping delays and accelerates production.

- Global Standardization: A partner with multiple locations using uniform BGA reballing processes ensures consistent quality worldwide.

- Simplified Logistics: Managing a single provider streamlines supply chain coordination, reducing operational complexity.

- Regulatory Compliance Across Regions: A global provider with regional facilities ensures adherence to local regulations while maintaining high-quality standards.

Reducing lead times is a competitive advantage in industries where production delays can cost millions. A streamlined approach to component sourcing solutions and BGA reballing prevents supply chain disruptions and ensures on-time delivery of critical components.

What to Look for in a Global BGA Reballing Partner

Selecting the right BGA reballing company with quality control standards is essential to optimizing efficiency, quality, and supply chain resilience. Key factors to consider include:

- Global Presence: Multiple facilities worldwide, all adhering to the same rigorous BGA reballing standards. A well-established global footprint ensures redundancy, supply chain resilience, and the ability to meet regional compliance requirements while maintaining consistent quality across all locations.

- Robust Sourcing Capabilities: A strong supply network to quickly access and process components. Look for a partner with diverse supplier relationships, efficient procurement strategies, and the flexibility to scale operations based on demand. Whether sourcing obsolete components or managing high-volume production, an agile partner ensures steady supply without compromising lead times or quality.

- End-to-End Traceability & Quality Control: Full transparency and compliance with industry standards to ensure reliability. Look for a partner with quality certifications and accreditations, such as ISO/IEC 17025, AS6171, and AS9120, which demonstrate adherence to stringent quality management systems and documented processes for regulatory compliance.

A reliable component sourcing solutions and BGA reballing partner should also have technical expertise and implement continuous process improvement to maintain high standards. Engineering capabilities, rigorous training, and adherence to evolving industry requirements ensure precision and reliability. Prioritizing a provider with these strengths enhances long-term operational stability and product quality.

The Strategic Advantage of an Integrated Approach

In today’s fast-paced electronics industry, working with a global, single-source partner for BGA reballing is the key to improving lead times, reducing risk, and ensuring consistent quality. A one-stop approach simplifies the process, providing seamless component preparation for industries where reliability is paramount.

Beyond efficiency, a trusted partner ensures you receive quality-verified components that meet industry standards. This proactive approach reduces failure rates, improves product longevity, and enhances overall supply chain resilience.

For companies in high-reliability sectors, choosing a trusted, full-service provider for sourcing and reballing BGAs is more than just a convenience—it’s a strategic advantage.

Read more:

- Beyond ISO Standards: Electronic Components for Defense and Aerospace Should be Subject to Higher Standards of Quality Testing

- Proactive Supply Chain Risk Management for Aerospace and Defense

- 3 Strategies to Strengthen Your Military or Aerospace Electronics Supply Chain